Introl DC100A

Series of Brushless Motor Controllers

The Introl DC100 series was designed, developed and is manufactured by Introl Design, Inc. to control three phase brushless DC motors. The DC100 is ideal for controlling general purpose brushless motors, or high per- formance servo motors, in tight and responsive servo loops. This controller provides all the advantages of DC brush type motors without the maintenance associated with brushes. Hall effect sensors supply commutation information, while encoder feedback supplies velocity information. Set-up requirements are easy to understand potentiometer adjustments. Isolated control circuitry allows quick and easy interface to other equipment without the requirement of isolation transformers or other isolation circuitry. Indicators include power on, run, current limit, fault, and bus voltage. The DC100 has been designed as a low cost, high performance alternative to brush type controls or expensive servo systems, up to 1'/ hp DC. (Larger models will be available soon.) This controller is protected against undervoltage, overvoltage, and overcurrent. Applications for the DC100 include indexing, positioning, synchronizing, precision speed control, spindle drives, and many others.

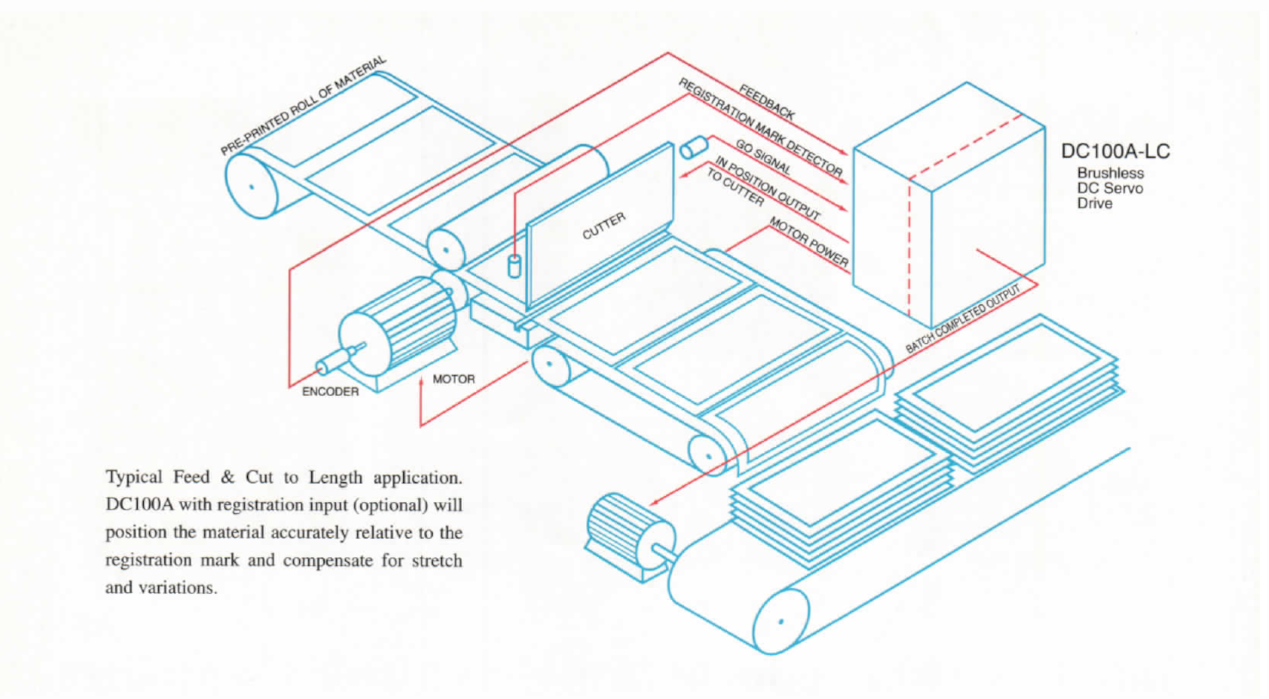

Length control Option:

The length control card mounts internal to the DC100 drive, adding 1 inch to the width, converting it to a stand alone single axis controller. The length control card utilizes differential encoder inputs with x4 logic providing 4000 counts of position resolution per motor revolution. All parameters can be programmed on the fly, and are installed through a serial communication link with one of Introl’s Operator Interfaces, or a computer. As a stand alone, the length controller can be programmed with a single preset, executed each time the run input is initiated, or have one of four preset indexes selected externally. All inputs are optoisolated, with an isolated 12 vde supply, included as standard, for supplying power to optoisolators. Index complete and batch complete outputs are uncommitted phototransistor outputs.

Operator Interface Options:

Introl manufactures a variety of operator interfaces for positioning or speed control, easily programmed and operated. The thumbwheel and pushbutton switches with LED indicators give the operator simple but effective local interface to process control. Any Introl interface doubles as a programmer, eliminating additional communication equipment required to set up initial parameters in the length controller card. Pushbutton and selector switches are rugged industrial switches, and connected to a printed circuit board for reduced wiring. Thumbwheel switches and LED indicators are also connected to a printed circuit board, monitored by an on-board microcontroller, communicating information to the length controller card through serial communication, reducing field wiring, improving noise immunity, and reliability.

Specification

Drive Specifications

- Input power: 230 vac (115 vac optional) single phase

- Line frequency: 50/60 Hz

- Output Current:

- 115 vac input(optional) 8.5 Amps at 17 kHz

- 230 vac input

- 6.0 Amps at 17 kHz

- optional 8.5 Amps at 12 kHz

- Bus Voltage:

- 115 vac input(optional): 160 vdc

- 230 vac input: 320 vdc

- Drive Service Factor: 1.0

- Duty: Continuous

- Reference Input Signal: 0 to ±10 vdc

- Modulation Frequency: 17 kHz or 12 kHz

- Commutation Feedback: Hall Effect Sensors

- Velocity Feedback: 1000 ppr Encoder

Length Controller Specifications

- Feedback: 1000 ppr differential encoder

- Isolated Power for Optos: 12 vdc

- Maximum Speed: 1800 rmp (or 4000 rpm optional)

- Inputs(8): opto isolated 5 to 12 vdc

- Outputs(2): uncommitted phototransistor 50 mA max

Drive Enable Output: rely- Set-Up (serial RS232 - 2400 baud):

- PID: 0 to 99%

- Accel/Decel: 0 to 9,999 ms

- Velocity: 9 to 99%

- Batch: 9 to 999

- Jog Speed: 9 to 99%

- Position: 0 to 9,999,999 counts

- Output Reference to Drive: 0 to ±10 vdc

- Encoder Output to Drive: Ch A and Ch b singel ended

Operating Conditions

- Line Voltage Variation: ±10%

- Line Frequency Variation: ±2 Hz

- Ambient Temperature: 0 to 50°C(32° to 122°F)

- Altitude: to 3300 above sea level

- Humidity: up to 95% non-condensing

- Physical Dimensions: 5.4W x 10,0H x 6.5D

Quick Contact

If you have any questions or would like to book a session please contact us.